By Andy Billingham, Managing Director – EMKA (UK) Ltd

The continued development of cabinet hardware with enhanced security has always been important and accounted for much of the evolution in such products – today we are seeing a refinement of this process with major manufacturers bringing through countless small improvements in mainstream ranges as well as innovative solutions in new areas.

Perhaps because this has been a continuous process over many years the area of cabinet locking technology is one that is often perceived as moving slowly. However EMKA is a long term market leader who has recently recognised a step-change requirement from customers for security oriented performance in its extensive range. As part of this process a number of sophisticated design initiatives have been developed into products which meet these needs. Included in this have been additions such as the 1155 combination swinghandle and the1154 vandal resistant swinghandle, in both the standard zinc die-cast and now in stainless steel. Not only have the materials been increased in specification, but many crucial features have been incorporated at the same time – such as recessing the handle into the door – making it suitable for both vandal and harsh environments.

For mainstream cabinets and enclosures innovation is exemplified in the 1325 swinghandle design which takes modular flexibility to a new level in this market. Designed specifically for electrical/electronic cabinets the stylish 1325 enables lock selection even after installation with a complete range of inserts to match common industry requirements.

For mainstream cabinets and enclosures innovation is exemplified in the 1325 swinghandle design which takes modular flexibility to a new level in this market. Designed specifically for electrical/electronic cabinets the stylish 1325 enables lock selection even after installation with a complete range of inserts to match common industry requirements.

A significant feature here is this ability to swap the lock mechanism at any stage thus enabling flexibility at production and installation stages – even post installation. Along with a precision rod control system, the complete installation provides a quiet and robust operation resulting from optimal use of modern engineering plastics and manufacturing techniques.

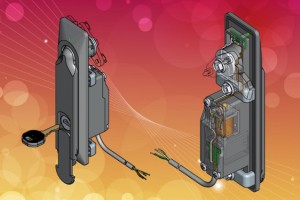

The ultimate in security consciousness for many situations would be to incorporate the highly flexible Electronic Locking Modules – ELM – into a cabinet. This incorporates the ability to upgrade from standard key locking swinghandles by simply changing the lock module for the electronic module. The ELM offers the benefits of a transponder key (with up to 4 billion possible combinations) or remote locking as either a stand-alone option or a fully Networked version, with the ability to generate a complete access log. Remote locking in this case would include digital pad, system management enabled computer addressing or finger print/retinal scanner. When combined with concealed hinges the resulting installation need not have an external handle or other obvious point of entry. Typically an engineer could visit a remote site, then use mobile phone communication to open the cabinet directly, or to call for it to be opened by the site control centre and simply close the door when finished.

The ultimate in security consciousness for many situations would be to incorporate the highly flexible Electronic Locking Modules – ELM – into a cabinet. This incorporates the ability to upgrade from standard key locking swinghandles by simply changing the lock module for the electronic module. The ELM offers the benefits of a transponder key (with up to 4 billion possible combinations) or remote locking as either a stand-alone option or a fully Networked version, with the ability to generate a complete access log. Remote locking in this case would include digital pad, system management enabled computer addressing or finger print/retinal scanner. When combined with concealed hinges the resulting installation need not have an external handle or other obvious point of entry. Typically an engineer could visit a remote site, then use mobile phone communication to open the cabinet directly, or to call for it to be opened by the site control centre and simply close the door when finished.

A novel development from EMKA is their Agent E program – comprising a unitary electronic release swing handle with battery power – so simplifying installation while enabling either individual radio key unlocking or central operation. This does not need hard wiring and may be installed on individual cabinets or large applications with many suites of cabinets. The Agent-E Manager remote software offers the possibility of wireless data transfer via an integral radio module whereby data can be transferred to a control station and/or master office. This enables the release of handles to be actioned remotely as well as control event logging. In a retro-fit application for example it is a simple matter to replace the existing mechanical lock with an electronic swing handle with no wiring necessary – set up and updates being by laptop.

This Agent E Wireless lock system is ideal for integrating decentralised single cabinets into a core access control system with easy expandability into additional later installation equipment or for retrofit to update old equipment for integration within an updating program.

The system is upgradable from Basic to Professional and Superior. Basic operation is by means of a personal micro transmitter – similar to a car radio-key – which is configurable to a master key plan and offers USB memory download of who, when, where.

In addition online systems enable remote configuration of all handles, reading of door status, remote handle opening and event memory readout.

A typical requirement along similar, but lower tech’ lines, has come from a major public utility, where standard insert developments have led to customer specified designs. In this case the addition of a specific square insert was required with security pin to prevent standard tool operation. The insert also has a special salt resistant coating to suit the environment conditions as specified by the customer.

A typical requirement along similar, but lower tech’ lines, has come from a major public utility, where standard insert developments have led to customer specified designs. In this case the addition of a specific square insert was required with security pin to prevent standard tool operation. The insert also has a special salt resistant coating to suit the environment conditions as specified by the customer.

Alongside locking developments continue in enclosure hinging with a view to enhanced security – these include the likes of additional materials, such as with the 1056 ranges which now have more polyamide versions and stainless steel, again to enable customer problems like harsh environment to be resolved. Blind fixing of hinges has been an issue for some time and EMKA have increased the number of hinges that can be fitted with a single pin. This has the double benefit of greatly reducing the fitting times during assembly while also enhancing security with a “through-panel” tamper resistant blind fixing.

As previously mentioned material additions to certain ranges have given the customer more options to solve more problems. Extended ranges of polyamide products offer alternatives to die-cast in many applications for reasons of superior performance and lower cost, often with longer life, while for more extreme duty we have seen additional stainless steel production coming through in both hinges and locks.

Concurrently significant progress has been made in Sealing, where developments include a number of Low Smoke and Low Toxic versions of standard gasket sections, produced to suit problem areas such as those where installation specifications include underground sites, or anywhere there is a potential smoke hazard within a confined space. In terms of the security of technology regarding Electro-Magnetic Compatibility – we have seen an increased number of applications with requirements for both EMC and IP protection combined in one gasket. This need has been met by EMKA engineers who succeeded in producing a number of sections with high attenuation against magnetic, plain wave and electrical interference, such that now a complete system is available for the specialist cabinet builder to incorporate into his custom designs.