In the busy life of a manufacturing engineer it is easy to lose sight of standard options where the default choice will do – so it is useful to consider some simple EMKA options of extruded gasket profiles to suit varying applications for industrial cabinets/enclosures, specialist vehicles, HVACR, railways and similar.

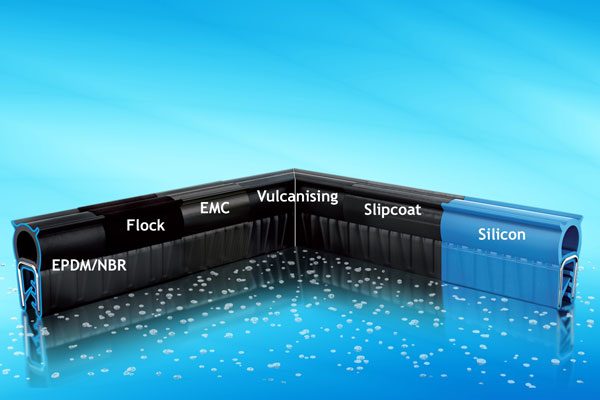

These include: EPDM/NBR – excellent general purpose industrial materials for IP protection, with good chemical resistance, available in stock and custom sizes, well know and understood by users, easy to handle and install.

Flock coating – a scratch-free coating to provide a smooth sliding action popular for windows.

EMC (coating) – for electro-magnetic compatibility to maintain or increase the protection of sensitive equipment from external EM radiation – or to protect external equipment from the internal generation of EM.

Vulcanising – a tough resilient way to form joints, frames and continuous sections which forms an integral material connection between the extruded ends which offers greater strength and performance than gluing.

Slipcoat – a simple coating process to redress the effect of friction.

Silicon – high temperature, fire resistant for rail, tunnels etc., food industry.

Of these perhaps of particular interest in time-saving and quality enhancement is the provision of pre-assembled gasket rings and frames. Proper sealing of ends and corners is essential to maintaining full sealing performance of a gasket profile, thus eliminating problems of “cutting short” which leaves a gap in the installed gasket strip, also addressing the problem of sealing into a square corner – otherwise often achieved by running the gasket round and creasing the material or by cutting and not adequately sealing.

Pre-assembled gasket is ideal for rapid application to door frames or apertures such as skylights, vents, access panels in electrical/electronic cabinets or enclosures – also for vehicle OEMs for car, truck and coach doors, as well as for caravans, railway coaches and specialist vehicles like ambulances and fire trucks.

Standard shapes include butt joins and right-angle joins enabling rings and frames as well as combinations to be produced in steel inserted profiles. Assembly is very simple by pushing or knocking onto a flange.

To discuss standard options or custom capability contact us here.